Short term course on Compliant Mechanisms

Minimum qualification:

BTech degree in Mechanical, Aerospace, or allied Engineering; Current BTech students who have completed third year are also welcome.

Prerequisite:

Familiarity with kinematics, mechanics of deformable materials, and finite element analysis.

Course Schedule

June 9 – 14, 2025

Course Mode: Offline

Venue: IISc Campus, Bengaluru

Registration Deadline: 6th June 2025

Course Fee

₹ 20000 Plus 18% GST

| Course Fee | 20000 |

| 18% GST | 3600 |

| Total | 23600 |

G. K. Ananthasuresh

Professor

Course content

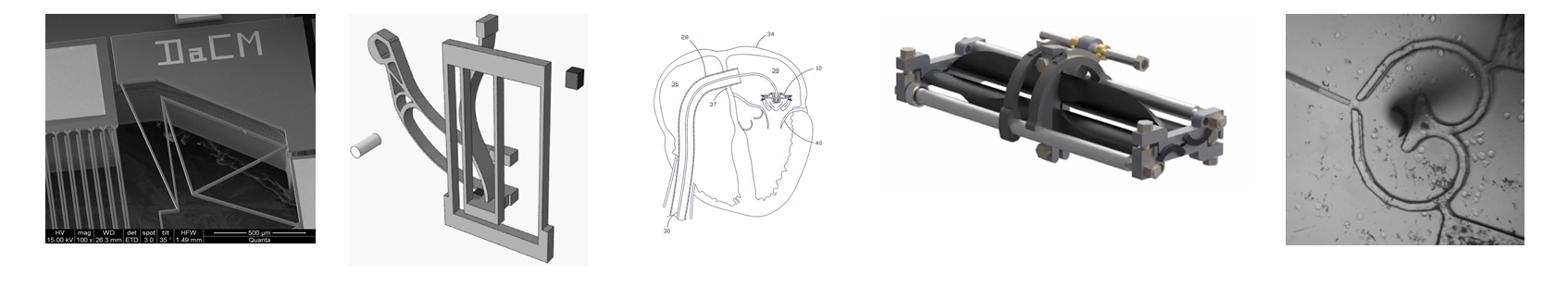

Compliant Mechanisms rely on elastic deformation to transmit, transform, and transduce motion, force, and energy. Although they may sometimes consist of rigid segments and kinematic pairs (i.e., joints), they are mostly understood as deformable elastic continua that can be made as single-piece entities that do not need assembly. Hence, they are suitable for almost any size (macro to nano), material, and manufacturing process. Their advantages include reduced manufacturing cost, improved precision due to the absence of backlash, no need for lubrication or maintenance, compact size, etc. The challenges include reduced mechanical advantage and efficiency, special attention to be paid for dynamic response and fatigue design, and the right choice of materials for a practical application.

This course provides a comprehensive view of research and development in compliant mechanisms spanning over the past four decades and covering the following:

| Systematics | From kinematic pairs to elastic pairs, extended Grübler’s formula, Maxwell-Calladine rule for mobility analysis |

| Energetics | Mechanical advantage and efficiency; static balancing; bistability; multi-stability; zero- and negative-stiffness mechanical elements |

| Analysis | Geometrically nonlinear finite element analysis; pseudo-rigid-body model; spring-mass-lever model; stiffness ellipsoids; beam constraint models; and non-dimensional kinetoelastic models |

| Synthesis | Extended Burmester method; topology optimization; instant centre graphical method; selection using feasibility maps; building-block method; hands-on compliant mechanism kit |

| Applications | Hand-held tools; precision instruments; MEMS; biomedical devices including surgical tools; automotive components; aerospace mechanisms including deployable structures; human-assistive devices; continuum and soft robotics; and more |

Course structure

Lectures and hands-on sessions will be in 3:1 ratio for a total of 36 h plus 4 h for discussions. Exercises, working with the state-of-the-art software, creative design, prototyping, a written examination and a project presentation at the end are part of the course. For interested participants who complete the course, a personalized follow-up course for exploring own designs is also possible at a mutually convenient time.

Who is eligible?

- Anyone from academic institutions, R&D institutions, and industry with a bachelor’s or higher degree in mechanical engineering or any other allied engineering disciplines. Freelancers, inventors, and designers from startups are also welcome.

- Undergraduate student who completed two years or four semesters of bachelor’s programme in mechanical engineering.